ISI 32-1e Determination of Starch Size Distribution by Screening

| 1. Scope |

The method is applicable to starch

|

LT 1970 Rev. LT 7 Feb1999 |

|

| 2. Principle |

Starch size distribution is determined by screening

|

||

| 3. Apparatus |

3.1 Screening set of lit, one or more screens and bottom 3.2 Laboratory scale |

||

| 4. Procedure | Weigh TARA of each screen and bottom | ||

| Weigh 100 g starch sample and transfer to top screen. | |||

| Shake stack of screens until fines through top screen is negligible. | |||

| Remove top screen and shake until fines through next screen are negligible and so on until all screens are removed. | |||

|

Weigh TOTAL of each screen and bottom

|

|||

| 5. Calculation | NETTO = TOTAL - TARA of each screen and bottom | ||

| GRAND NETTO = Sum of individual NETTO | |||

| Report with one decimal each starch fraction as percent of GRAND TOTAL and characterised by the trapping mesh width (opening) in micrometer. | |||

|

Example: 0 % > 250 µm 0.1% > 125 µm, (< 250 µm) 2.1% > 63 µm, (< 125 µm) 98.2 % < 63 µm

|

Mesh width in parenthesis may be omitted if it is obvious that fractions are not accumulated | ||

| 6. Notes |

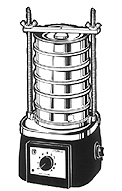

Preferably use a 200 mm dim. vibrator sieve shaker and shake for 15

min. The following sizes belongs to an ISO main serie: |

Screen Conversion Table | |

| DIN 4188 | equivalent ASTM | ||

| 0.063 mm | 230 mesh | ||

| 0.071 mm | 200 mesh | ||

| 0.125 mm | 120 mesh | ||

| 0.180 mm | 80 mesh | ||

| 0.250 mm | 60 mesh | ||

| 0.355 mm | 45 mesh | ||

| 7. Image |

|

Sieve shaker | |

Comments

Post a Comment